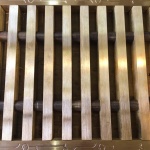

The next project was a real challenge for the Brass Workshop. In a private residence, it was necessary to make 148 meters of convector lattices. For installation preparation of landing surfaces was necessary. Our craftsmen cut the steel case of the already mounted serial convectors made for the installation of universal plastic converter grids.

Further, according to the project, a brass strip 10x17mm was made in the workshop, which is not mass-produced. Strip cutting took almost 700 hours of work. After cutting the blanks, all the parts of the brass convector lattices were manually assembled for mechanical connections. Each grate has a large number of screws. The assembly of the lattice turned into a test for the professional suitability of mechanic assembly machines in our workshop. The best craftsmen spent one working day to assemble one grate.

Today, utilitarian objects – convection lattices have turned into real decorative ornaments of a huge house. We proudly performed a very difficult job and are very pleased that our convection lattices are in perfect harmony with the typeset parquet and marble.